The Magic of Stainless Steel Mix Tanks: Unlocking the Potential of Fermentation

Posted on August 10, 2023 by digitguider

Fermentation is a fascinating and age-old process that has been used for centuries to transform raw materials into a wide range of products, from beverages like beer and wine to essential pharmaceuticals and biofuels. Central to the success of fermentation is the use of advanced equipment, and stainless steel mix tanks, particularly stainless steel fermenters, have emerged as the preferred choice in modern fermentation processes. In this blog, we will explore the magic of stainless steel mix tanks and how they unlock the full potential of fermentation in various industries.

The Role of Stainless Steel Mix Tanks in Fermentation:

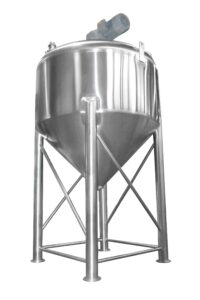

Stainless steel mix tanks, often referred to as fermenters in the context of fermentation, are specifically designed vessels used to create an ideal environment for microbial growth. These tanks play a vital role in controlling key parameters such as temperature, agitation, and aeration, which are essential for the growth and activity of microorganisms during fermentation.

The Ideal Material for Fermenters:

The choice of material for fermenters is critical, as it directly affects the quality and outcome of the fermentation process. Stainless steel stands out as the ideal material for fermenters due to its unique properties, which contribute significantly to successful fermentation.

- Corrosion Resistance: Stainless steel is renowned for its exceptional resistance to corrosion and rust, making it suitable for the harsh and often acidic environments found in fermentation processes. Unlike other materials that may deteriorate over time, stainless steel fermenters maintain their integrity and hygienic properties, ensuring the purity of the final product.

- Hygiene and Cleanability: Maintaining a hygienic environment is of utmost importance in fermentation processes. Stainless steel has a smooth and non-porous surface, making it easy to clean and sanitize thoroughly. This characteristic reduces the risk of contamination and ensures the consistency and quality of the fermented product.

- High-Temperature Resistance: Fermentation processes often involve temperature control, whether it’s maintaining a specific temperature for brewing beer or controlling the fermentation rate in biotechnology. Stainless steel fermenters can withstand high temperatures without deformation or structural damage, providing precise temperature control throughout the process.

- Longevity and Durability: Stainless steel fermenters are built to last, providing a long lifespan and continued performance even under demanding conditions. This durability translates to a cost-effective investment, as the fermenter requires minimal maintenance and has reduced replacement frequency.

Unlock the Full Potential of Fermentation with Cedarstone Industry LLC’s Stainless Steel Fermenters!

Experience the magic of stainless steel mix tanks as we take your fermentation processes to new heights. Our corrosion-resistant and hygienic stainless steel fermenters create the ideal environment for microbial growth, ensuring pure and top-quality products. With precise temperature control and customization options, we cater to diverse industries, from brewing to biotechnology and pharmaceuticals. Embrace longevity and durability, reducing maintenance costs and maximizing efficiency. Discover the art of crafting beer with our aesthetically appealing fermenters. Let Cedarstone Industry LLC unlock the endless possibilities of fermentation for your business!