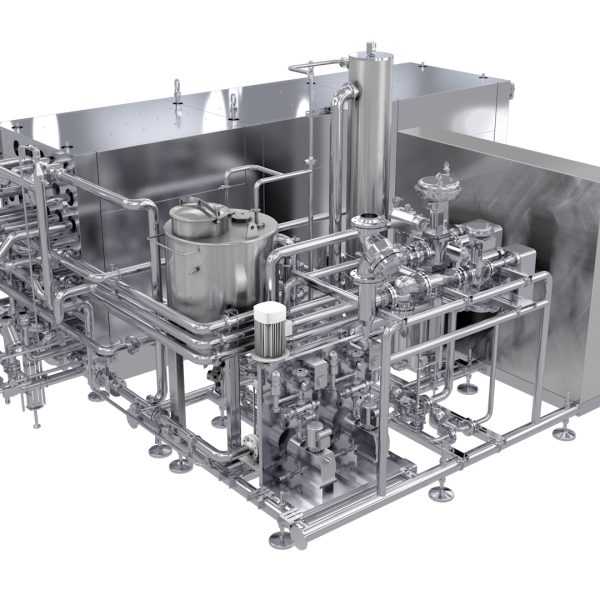

CIP & UHT System Manufacturer

Cleaning and pasteurization are vital (and required) in the food and beverage industry. Many industries adopt clean-in-place (CIP) systems or ultra-high temperature (UHT) systems to achieve this. At Cedarstone Industry, we understand the importance of these procedures, but we also know how important the equipment’s quality is. We are experience CIP and UHT system manufacturers, and our products are made with high-quality materials that are food grade and built to last. So, whether you need clean-in-place equipment or ultra-high temperature processing equipment, we’ve got you covered. Shop our selection today, and let us know if you have any questions about our CIP or UHT systems. One of our experts will be happy to help.