Are you on the market for commercial extraction systems? If so, then you should definitely contact the experts at Cedarstone Industry. With over two decades in the sanitary industry, we have the expertise necessary to get you high-quality products and services available. Located in Houston, Texas, we have provided quality equipment to companies such as Heineken, Anheuser-Busch, GEA, Tetra Pak, Coca-Cola, GE Pharmaceutic, and a wide range of other commercial breweries over the past two decades. Our company is proud to offer clients services in engineering, constructing, commissioning, and servicing a production line in your plan. Additionally, we can also make existing line upgrades regardless of the type of brewing tanks and equipment you need.

Extraction Systems

As a matter of fact, Cedarstone Industry and our partners have been in the industry since 1992. Due to our consistent and rigorous commitment to quality, we have come to evolve into an all-around entity, with a large scale of services and products. Some of the services and products we deal with include supplying turn-key installation services, brewing tank manufacturing, CIP, UHT, water purification, commercial beer brewing equipment, extraction equipment, oil extraction, extraction machines, extraction methods, and other services that adhere to regulatory compliance. Above all, we aim to use our expertise and work ethic to help our clients reach their commercial and financial goals.

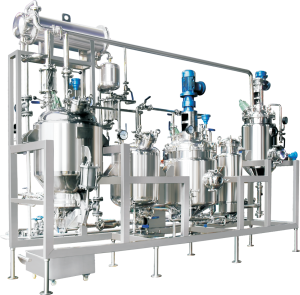

Cedarstone Industry’s Extraction Systems

If you are searching for commercial extraction equipment and systems, then we are an excellent choice for you and your company. As a manufacturer of extraction equipment, we are able to provide high-quality cannabis the hemp oil market great closed low-pressure ethanol systems of extraction. Whether it’s cannabis oil or cannabis alcohol, we’ve got you covered.

The ethanol extraction systems we offer are great for commercial producers and are more efficient and cost-effective methods than CO2 supercritical fluid extraction. In addition, our line of extraction systems includes a series of extraction, distillation, and also crystallization products. Even more, our methods extremely sage for cannabis hemp oil extraction technology. Our equipment and systems will provide both the operator and the end consumer quality and safe extraction methods while also providing useful service for many years to come. As a result, we’ll be able to help your business grow in the short-term and then long-term.

Generally, there is a consensus that ethanol extraction systems are the best method of extracting CBD for commercial purposes. For one, ethanol extracts both oil-soluble compounds and water. And when used in freezing temperatures, ethanol can actually selectively extract particular terpenes and cannabinoids from the cannabis, leaving other undesirable molecules such as lipids and waxes behind.

Fortunately for our clients, we offer complete turnkey extraction systems, from 100L and upwards. Cedarstone Industry’s turnkey systems include the following major components:

Extraction vessel

- Primary and secondary cooling ethanol tanks

- The extraction tank

- A single filter

- Storage tank for extracted liquids

- Ethanol recovery concentrator

- A storage tank for concentrated liquids

- A recycling ethanol tank for storage

- Ethanol distillation tower

- Concentrated ethanol tanks

- Quality ethanol pumps

- Concentrate pumps

- Extraction pumps

Centrifuge Extractor Machines and Equipment

Cedarstone Industry is very pleased to say that we offer batch production centrifuge extraction machines and products. Our centrifuge machines are great for a number of reasons. For one, these machines are great for low-temperature hemp and ethanol extraction processes. Cedarstone’s series of centrifuges are very easy to maintain, easy to operate, and can also be configured to the client’s specific needs and requirements. Additionally, these extractor machines are great for high-speed and safe operations. The features included in the machines include the following:

- Compliance with the most up to date standards, directives, and GMP requirements

- Complete delivery of modular design, without the need for on-site installation

- Quality transmission and motor parts that are enclosed for safe operations

- Advanced and quality control systems and interface for HMI operations in order to achieve a single operation

- Motors that are explosive-prof from Toshiba or equivalent

- Touch screen and Siemens PLC

- The optimization of designs in order to allow for temperature extraction at -6o degrees Celsius

- High-quality and reasonable structure design for sealing to achieve reliable sealing of bearing

- EPDM good-grade seal and 316L materials

- Great sanitary designs

- Automatic valves that are capable of configurations for the realization of automatic control for discharging and feeding

- Exterior stationary barrels that come with cooling jackets

- Adjustable agitation time setting and speeds

If you wish to learn more about our centrifuge extractor, make sure to give a call or fill out the form available at one of our product pages.

Post-Extraction Equipment Such as Molecular Distillation Systems

Centrifuge Extractor

In case you weren’t aware, molecular distillation is a special type of liquid-liquid separation technology. This type of technology is different from traditional distillation that uses the boiling point difference separation principle. By different substances, molecular movement of an average free path difference, separation is achieved.

Generally speaking, the industry considers molecular distillation as the safest mode of separation and for the purification of the thermally unstable molecules and related compounds that have low volatility and an elevated boiling point. Additionally, this process will distinguish the short residence in the zone of molecular evaporator that is exposed to heat and low operating temperatures thanks to vacuum in the space distillation.

Wiped Film Evaporation System (WFE)

Here is how this system works:

Feed material is delivered into the main jacketed evaporator. And with consistent heat from the jacket, a thing film in turbulent conditions will form. Afterward, it will push forward in spiral motions. At the center, and internal condenser will provide a short-distance path. This path is for vapor molecules traveling from the heated surface towards the condenser cooling surface.

During this downward journey, lighter fractions of liquids will start to vaporize and then move to the internal condenser. They will then condense and be captured and separated into the distillate receiving flask. Some heavier residue materials such as chlorophyll, salts, sugars, and heavy will not evaporate. Instead, they will travel the length of the main evaporator body. Then, they will flow into the residue receiving flask.

Contact Us

If you want to learn more about our great services and products, give us a quick call. You can reach Cedarstone Industry by calling (281) 397-3700 or contacting us online. Above all, we aim to help our clients with their extraction system operations. We do so by offering efficient and cost-effective solutions to their industrial problems. Moreover, you can learn more about our extraction systems and equipment online.