Discover The Crucial Role of Mixing Pits in Food Processing Plants

Posted on February 5, 2024 by digitguider

In the intricate world of food processing, precision and consistency are paramount. One critical component that plays a pivotal role in ensuring these aspects is the mixing pit, specifically designed to integrate stainless steel mixing tanks seamlessly. In this blog, we will explore the indispensable role of mixing pits in food processing plants and the significance of utilizing stainless steel in these essential vessels.

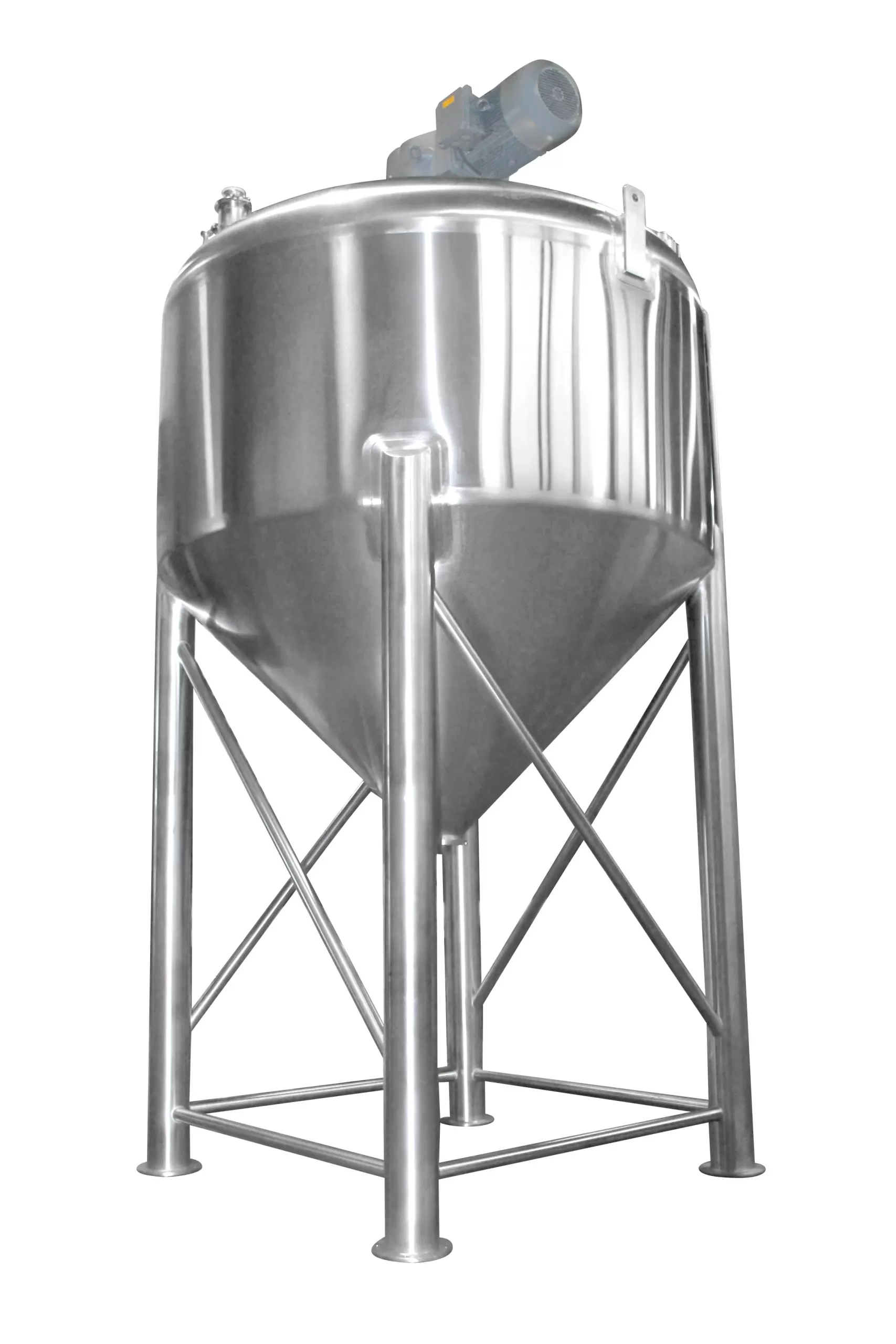

The Foundation: Stainless Steel Mixing Tanks

Stainless steel has become the material of choice for mixing tanks in food processing plants, and for good reason. Renowned for its durability, corrosion resistance, and non-reactive properties, stainless steel ensures that the integrity of the food products remains intact throughout the mixing process. Additionally, its smooth and non-porous surface facilitates thorough cleaning and sterilization, meeting the stringent hygiene standards mandated by the food industry.

The Heart of Precision Mixing: Mixing Pits

Mixing pits serve as the beating heart of food processing plants, where raw ingredients transform into the delectable products that reach our tables. These specialized pits are designed to accommodate stainless steel mixing tanks, providing a controlled environment for the precise blending of ingredients. The dimensions of the mixing pit play a crucial role, ensuring that the tank can be maneuvered efficiently and that the mixing process is uniform.

Homogeneous Blending for Consistency

In the realm of food processing, consistency in product quality is non-negotiable. The mixing pit, housing stainless steel tanks, enables homogeneous blending of ingredients. Whether it’s the creation of sauces, marinades, or dough for baked goods, the controlled environment of the mixing pit ensures that every batch meets the exact specifications, maintaining the flavor profile and texture that consumers expect.

Temperature Control and Jacketed Tanks

Temperature control is a critical factor in many food processing applications. Mixing pits equipped with stainless steel jacketed tanks allow for precise regulation of temperature during the mixing process. This feature is particularly essential for industries where temperature-sensitive ingredients are involved, such as chocolate confectionery or dairy processing. The stainless steel jacket provides a layer of insulation, preventing heat loss or gain and ensuring that the product retains its desired characteristics.

Hygiene and Food Safety Compliance

The food industry operates under stringent hygiene and safety regulations. Mixing pits, when combined with stainless steel tanks, offer a solution that aligns perfectly with these requirements. Stainless steel’s inherent resistance to corrosion and bacterial growth, coupled with the smooth surfaces that are easy to clean, make it an ideal material for maintaining the highest standards of hygiene in food processing plants.

Cedarstone Industry LLC: Tailored Mixing Solutions for Diverse Industries

At Cedarstone Industry LLC, we specialize in crafting custom-designed low and high-shear mixers and tanks tailored to diverse industries. Whether you’re in cosmetics, pharmaceuticals, chemicals, or food and beverages, our exclusive line of mixing tanks, storage tanks, flange-top tanks, and cosmetic mixing tanks ensures compliance with industry regulations. Elevate your industrial processes with top-of-the-line technological solutions, and rest assured with our low-maintenance, reliable products that meet and exceed expectations across any industry.