Choosing the Right Food Grade IBC Tote for Your Specific Application

Posted on November 19, 2023 by digitguider

Food-grade IBC (Intermediate Bulk Container) totes have become indispensable in various industries, particularly in the food and beverage sector and the production of commercial alcohol. These versatile containers offer a safe and efficient means of storing, transporting, and dispensing liquids. Choosing the right food-grade IBC tote for your specific application is imperative to maintain the integrity and quality of your product. This blog post will delve into essential considerations for selecting the optimal food-grade IBC tote, emphasizing its relevance in commercial alcohol distilling equipment.

Material Composition

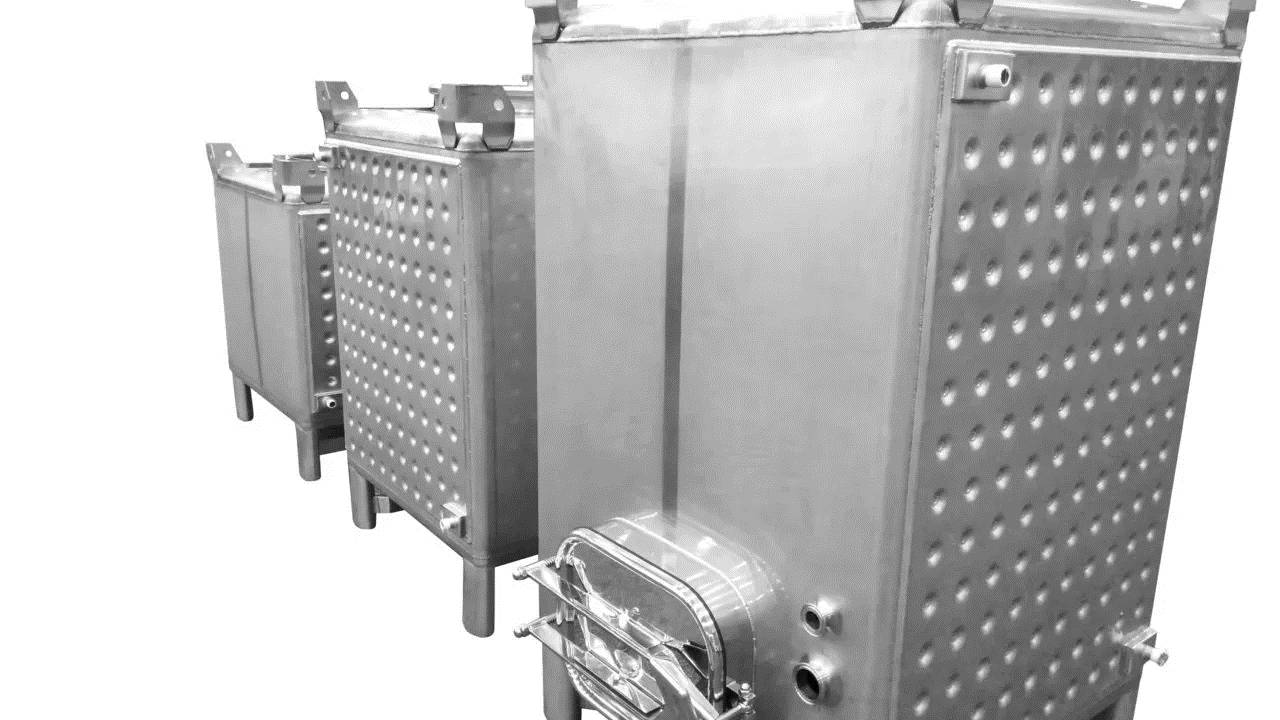

The material of the IBC tote is a critical factor in ensuring it meets food-grade standards. Opt for totes made from high-quality, food-grade materials such as FDA-approved polyethylene or stainless steel. These materials are non-reactive, corrosion-resistant, and specifically designed for contact with food and beverage products.

Capacity and Volume Requirements

Different applications in commercial alcohol distilling may necessitate varying tote capacities. Consider the volume of liquid you will be handling and choose an IBC tote with an appropriate capacity. This ensures efficient storage and transportation without the need for frequent refills or transfers.

Design and Configuration

Food-grade IBC totes come in various designs, including square, rectangular, and cylindrical shapes. Consider the space available in your distillery or production facility, as well as any constraints related to stacking or maneuvering the totes. Additionally, assess whether a top-fill or bottom-discharge configuration better suits your operational needs.

Outlet and Valve Options

The type of valve and outlet on the IBC tote plays a crucial role in efficient dispensing and product handling. Choose a tote with a valve that provides controlled flow rates suitable for your specific application. Additionally, consider any additional features like butterfly or ball valves for added convenience.

UN/DOT Certification

For applications involving the transportation of hazardous materials, including certain types of commercial alcohol, it’s imperative to choose a food-grade IBC tote that meets UN/DOT (United Nations/Department of Transportation) certification standards. This certification ensures that the tote is compliant with regulations for the safe transport of hazardous liquids.

Compatibility with Distilling Processes

Consider how the IBC tote integrates with your commercial alcohol distilling equipment. Ensure that it is compatible with your existing systems and can be easily connected for filling and emptying. This compatibility ensures seamless operations and minimizes the risk of spills or leaks.

Cleaning and Maintenance

Maintaining a high standard of hygiene is essential in food and beverage production, including commercial alcohol distilling. Choose a food-grade IBC tote that is designed for easy cleaning and sanitation. Look for features like smooth interior surfaces, accessible corners, and FDA-approved gaskets or seals.

Cedarstone Industry: Your Trusted Partner for Turn-Key Stainless Steel Solutions

At Cedarstone Industry LLC, we not only manufacture premium stainless tanks and systems, but we also excel in their seamless installation. With a track record of successful global projects, our team brings unparalleled expertise to every installation. Our commitment to quality control and progress supervision ensures a flawless process. We collaborate closely with clients to deliver turn-key solutions tailored for the food, beverage, extraction, and brewery industries. From stainless vessels to mixing tanks, aseptic tanks, and more, we offer a comprehensive range of industrial stainless steel equipment. Elevate your operations with Cedarstone Industry’s automation turnkey solutions.