A Comprehensive Guide to Tote IBCs: Efficient Solutions for Material Handling

Posted on September 10, 2023 by digitguider

In the dynamic world of material handling and storage, efficiency is paramount. Enter Tote IBCs, short for Intermediate Bulk Containers, the unsung heroes of industries ranging from chemicals to food processing. These versatile containers offer a reliable means of transporting, storing, and even dispensing various materials, all while minimizing waste and maximizing space.

In this comprehensive guide, we will delve into the world of Tote IBCs, covering everything from their basic structure to their applications, and even touch upon the intriguing concept of the Falling Film Evaporator. Buckle up for a journey through the world of efficient material management.

-

Unveiling the Tote IBC: What Are They?

Tote IBCs, as the name suggests, are intermediate-sized containers designed for bulk material handling. These versatile containers typically have capacities ranging from 275 to 330 gallons, although variations exist. What sets them apart is their ability to hold a substantial quantity of material while remaining easily maneuverable. Tote IBCs are made from robust materials like high-density polyethylene (HDPE) or stainless steel, ensuring durability and material compatibility.

-

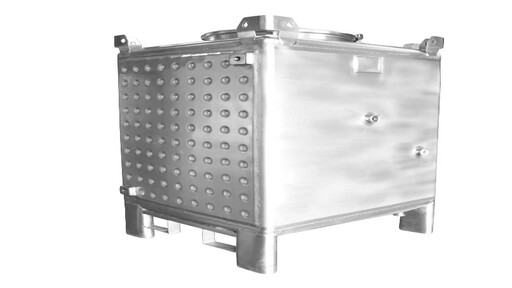

The Anatomy of Tote IBCs: Understanding the Components

To grasp the functionality of Tote IBCs, it’s essential to understand their anatomy. They consist of a sturdy frame or pallet base, which serves as both a foundation for the container and a means of facilitating transportation using forklifts or pallet jacks. On top of this base, there is the container itself, which can be either a flexible bag or a rigid, stackable tank. The top of the IBC typically features an access port or lid for easy filling and dispensing, often accompanied by valves and fittings for fluid materials.

-

Tote IBC Applications: Where Do They Shine?

Tote IBCs are versatile workhorses utilized across various industries. In the chemical sector, they’re indispensable for transporting hazardous chemicals safely due to their sturdy construction and leak-proof designs. In the food and beverage industry, they store liquids like syrups, juices, and edible oils, ensuring product quality and traceability. In agriculture, they handle fertilizers and pesticides efficiently. Moreover, Tote IBCs find applications in pharmaceuticals, cosmetics, and many more industries where safe and efficient material handling is paramount.

-

Bonus: Exploring Falling Film Evaporators and Tote IBCs

As we venture further into the realm of efficient material management, it’s worth mentioning the Falling Film Evaporator. This intriguing piece of equipment complements Tote IBCs in various industries, especially those dealing with concentrated liquids. Falling film evaporators efficiently and gently remove water or solvents from liquid products while preserving their quality and flavor. This process often finds synergy with the storage and transportation capabilities of Tote IBCs, creating a seamless workflow for industries like food processing and chemicals.

Efficiency Unleashed: The Power of Tote IBCs and Falling Film Evaporators

Elevate Your Material Handling Efficiency with Cedarstone Industries LLC! We specialize in innovative solutions like Tote IBCs that streamline bulk material transportation, storage, and dispensing. With sturdy construction and versatile designs, our Tote IBCs are tailored to meet your industry’s specific needs. And, for those looking to enhance processes further, we explore synergies with complementary equipment like Falling Film Evaporators. Join us in embracing efficient and eco-conscious material handling. Choose us for a brighter, greener, and more efficient future for your business!