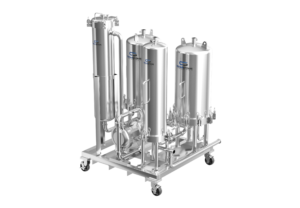

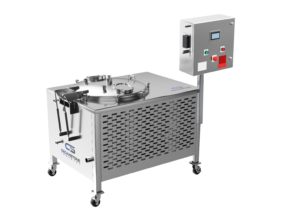

Are you inquiring about a supercritical CO2 extraction equipment? Cedarstone Industry it the very company you are searching for. They have the highest quality ethanol extraction equipment for your project. Cedarstone Industry is stationed in Houston, TX, and will supply you with your needs anywhere in the world.

Are you inquiring about a supercritical CO2 extraction equipment? Cedarstone Industry it the very company you are searching for. They have the highest quality ethanol extraction equipment for your project. Cedarstone Industry is stationed in Houston, TX, and will supply you with a top-quality machine no matter where you are. They have provided machines to Coca-Cola, Heineken, Bluebell, and other big-name companies.

It doesn’t matter if your company is big or small, they supply machines to any and every company that needs them. Some of these projects that these machines are great for are CBD oil, essential oils, brewing beer, or whatever else your project demands. Cedarstone Industry also services all of their machines. When you buy a machine from them, you won’t have to worry about its upkeep. Cedarstone Industry can come to you and take care of it. So, feel free to call if you are searching for extraction equipment. Cedarstone Industry has machines that compare in quality and productivity of supercritical CO2 extraction equipment. Let’s take a look at how CO2 and ethanol compare when it comes to quality.

What Is Supercritical CO2 Extraction Used For?

This system is known as supercritical fluid extraction (SFE). This is used for multiple industries and impacts our lives more than we realize. Whether it is pharmacology or food, many companies use CO2 extraction. One of the industries that benefit from the CO2 extraction process is the essential-oil companies. The new oil craze isn’t the only thing that makes essential oils popular. These oils are in perfumes and other cosmetics. They are even used in our spices.

CBD is another industry that benefits from supercritical CO2 extraction equipment. They are a growing industry and have been helping people mitigate pain for years. However, to have the right oil and for it to be a healthy substance for consumption, the oil needs to be extracted from the plant and purified.

The goal of extraction is to separate desired oils from their toxic compounds. This process is necessary to make the products safe for consumption. This process makes the plant extract microbiologically clean while also conserving the natural components.

Even though it may seem like the plant matter is harmless, it has pulled toxins from the soil. These toxins can make it dangerous for customers to consume. So, to ensure the safety of the product for consumers, an extraction system is necessary.

How Does Supercritical CO2 Extraction Work?

This extraction method uses pressurized carbon dioxide to pull the desired compounds from the plant materials. With supercritical CO2 extraction, it brings the temperature and pressures up to a critical point. This causes the CO2 to exude the properties of both a gas and a liquid. Once it hits this point, it is in a supercritical state and becomes a supercritical fluid. This fluid can dissolve porous materials allowing for the capture of the active compounds.

While this process takes longer and produces smaller amounts, it is the most desirable out of other extraction processes. One of the biggest industries for it is the cannabis industry. This process allows manufacturers to create full-spectrum cannabis products. These high pressures and temperatures are able to extract molecules like chlorophyll, omega 3 and 6 lipids, and waxes. Then it will go through a process named winterization where it will leave behind just the cannabinoid oil.

What is Ethanol? And How is it Better?

Ethanol extraction is also known as grain alcohol and ethyl alcohol. It is a colorless and evaporative flammable liquid that is efficient and effective. Ethanol is also safe for human consumption, according to the FDA. This solvent is in the production of food preservatives, as well as in the production of beer and wine.

The pluses of this method are that they are safer than butane and more effective than supercritical CO2. There are also more lenient storage limits, meaning fewer requirements. So, this solvent yields larger extract volumes than CO2 while also having fewer restrictions.

You also won’t miss out on being able to create full-spectrum cannabis products. Just like CO2, ethanol is a great solvent for creating full-spectrum hemp extracts and products.

Another bonus that ethanol has is that is is a renewable resource since it is made from corn. It is also a class 3 solvent with low toxic risks and leaves little to no residual solvent behind.

What Are Some of The Benefits of The Supercritical Method?

There are many benefits to this method. Whether that is a cleaner resource that is provided or a greener solution to the extraction method. These are some of the benefits of this method that are good to think about:

- makes sure that the collected components have not degenerated

- The use of non-toxic solvents which produces products that are chemically pure

- this process prevents oxidation because it runs without air

- produces little to no waste

- high selectivity of the process

- the potential of recirculation of the solvent which reduces costs

- fractionation of the collected substance as the process develops

- possibility to regulate the solubility of individual components in an effective manner

Another advantage of using a supercritical method is that the extraction rate can be as high as 95 percent when processing vegetable oil. With other mechanical pressing or traditional methods, their productivity is about only 60 to 80 percent.

When it comes to different solvents, CO2 is the safer, cheaper, and greener solvent. It is considered greener because it doesn’t give off the same emissions as fossil fuels. Using CO2 also creates a product that is more consistent and palatable.

The Cost of These Machines

Because of the accuracy and quality of ethanol extraction equipment, these machines can cost thousands, sometimes tens of thousands of dollars. Even though they can be costly, they compare well to other solvent-based approaches when it comes to safety and special facilities that are legally required. This equipment requires a high amount of training and isn’t something that is worth cutting corners on. With the ethanol solvent, you are probably getting one of the best methods for the production of your product.

Supercritical Fluid Extraction Vs Ethanol Extraction

This is the million dollar question because there are many factors which can limit your solvent options. The short answer is ethanol, for reasons we discuss shortly but the justification for this answer is a compromise between three key factors: selectivity, cost, and safety. Safety also happens to be the X-factor by virtue of the exponential effect it can have on cost.

Solvent selectivity

Molecules and solvents can be classified by their polarity: polar vs nonpolar (or somewhere in between). CBD is very nonpolar. Water is very polar. Adhering to the very old and very true adage, “like dissolves like”, we can correctly assume that water is ineffective for CBD extraction. While you may have heard of water (or “bubble”) hash, this is actually a physical separation of the trichomes from the rest of the plant. The potency of this extract peaks at around 45% CBD and is unsuitable for crystallization whereas solvent extracts reach 90% CBD and can be further processed to reach 99% after crystallization. For this reason, we will omit water hash from the discussion of high-throughput hemp processing.

Clearly, nonpolar solvents are chemically ideal for CBD extraction so does that mean ethanol is a nonpolar solvent? No. Ethanol is considered “somewhere in between” on the scale of nonpolar vs polar. Thus, it has the disadvantage of extracting polar molecules such as pigments, sugars, and- you guessed it- water. If ethanol is so much less selective than a common industrial nonpolar solvent such as butane or hexane, why would we use it? You guessed it- cost and safety.

Before we weigh the pros and cons of solvent safety, another common nonpolar extraction solvent deserves honorable mention- carbon dioxide.

When carbon dioxide is under enough pressure and temperature, it transitions to a fourth state of matter- a supercritical fluid. Extraction using carbon dioxide is called SFE (supercritical fluid extraction). In SFE, carbon dioxide is purchased very inexpensively in its liquid state and the pump on the CO2 machine brings it up to supercritical pressure while heaters bring it up to supercritical temperature. The pump must be very robust to achieve these pressures as well as the vessels and tubing in order to withstand these conditions safely. The end result is a SFE machine that is cost prohibitive for most start-ups. A “high capacity” SFE machine starts at $500,000 and can only extract approximately 25 pounds per hour whereas a similar throughput ethanol extraction unit costs about 10X less. That being said, carbon dioxide is the safest of the relevant extraction solvents being used in the industry today. But, you may ask, isn’t safety the X-factor? The answer is yes, but SFE has a major caveat: carbon dioxide also extracts lipids (AKA waxes and fats). Removal of lipids requires the painstaking and costly step of precipitation or “winterization”. Not only is this process inefficient but it negates the safety advantage of CO2 by requiring the use of ethanol. Is ethanol unsafe? No, it is again “somewhere in between”. Ethanol is more dangerous than carbon dioxide (after all, carbon dioxide is a fire extinguisher) but less dangerous than hydrocarbon solvents (i.e., hexane or butane).

Safety

For the sake of argument, let’s pretend that your hemp processing start-up company has the technical and engineering expertise to build a safe, reliable extraction facility with the equipment, infrastructure, and safeguards necessary to prevent a catastrophic accident involving the volatile solvent hexane or the gaseous butane or propane. Is your Fire Marshal willing to send his or her men and women into an explosive situation just so you can beta-test your cannabis facility in your proof-of-concept business venture? If you are a first-mover in that Fire Marshal’s jurisdiction, the answer is probably no. If entrepreneurs have already tried this and the result was a fire or explosion, the answer is a resounding NO. Per the NFPA codes, closed-loop light hydrocarbon extraction using butane or propane requires C1D1 construction which is very stringent and very high cost.

Let’s take this hypothetical situation one step further and assume that your Fire Marshal does in fact allow hydrocarbon extraction. Let’s also assume you aren’t using butane or propane due to the limitation in throughput inherent in pressurized batch extraction. That leaves us with pentane, hexane, or heptane- all of which behave almost identically with the exception of boiling point (this detail is inconsequential in regards to extraction but has significant implications in the crystallization process, more on that later). With the multitude of ethanol extraction and evaporation equipment on the market today, one might be tempted to reappropriate said equipment for use with, say, hexane. While this in theory may seem perfectly reasonable, the devil is in the details. There are many fittings and seals in this equipment and some of them aren’t trivial (ie, a centrifugal seal or evaporation plate exchanger). The manufacturer designs and sells this equipment for use with ethanol and therefore the seals are designed to be chemically compatible with ethanol, not hydrocarbons. Case in point- use of 190 proof ethanol denatured with heptane will void the warranty of most centrifuge extractors because even 5% hydrocarbon by volume will destroy the seals.

By now, we have made a case for ethanol based on selectivity and safety but it is a scant case at that. If we reduce the solvent temperature to below zero degrees Celsius, however, selectivity and safety become significantly better.

Here’s why cryo-ethanol improves selectivity and safety:

Temperature affects the rate at which processes occur

Cold ethanol does not have a higher affinity for CBD nor a lower affinity for pigments and lipids. Lower temperature slows down the rate at which molecules move from the solid material (hemp) into the liquid material (ethanol). This rate is called the mass transfer coefficient. CBD, pigments, and lipids all have their respective mass transfer coefficients at a given temperature. The great thing about CBD is that its mass transfer coefficient is still quite high at very low temperatures. This is not the case for lipids and pigments such as chlorophyll. So by manipulating the temperature and halting the extraction until just after the bulk of the CBD has entered the solvent, we can improve de facto selectivity.

Just as low temperature slows down the rate of mass transfer, low temperature slows the rate of evaporation. As you probably know, it is not the liquid itself that is flammable but rather the vapor and its access to oxygen in the atmosphere for combustion. Thus, cryo-ethanol is much less flammable and likewise much less explosive than at room temperature. In fact, at -40 C there are so few ethanol molecules evaporating from the liquid surface, if a match were struck just above the surface (not recommended), it would not ignite. Since there is no reason to have ethanol in open use, a closed-loop system allows for safe and efficient transfer of solvent in the extraction and evaporation room. The NFPA code for closed-loop ethanol extraction calls for C1D2 (as opposed to C1D1 for butane) which significantly brings down costs and complexity.

Finally, ethanol is safer not just in terms of fire hazard but also in terms of consumer safety. Ethanol is classified by the FDA as a Class 3 solvent with low toxicity. It can be present at concentrations up to 5000ppm and still be considered safe for consumption. Moreover, ethanol can be certified as food grade, Kosher, and Halal.

Cost

Ethanol may be one of the more expensive solvents to choose from but its high cost can be managed in some ways and mitigated in other ways. The largest savings can be accomplished through ethanol recovery in the evaporation process. This is essentially ethanol distillation and has become standard procedure in the cannabis industry. A major disadvantage of ethanol distillation is the formation of an ethanol-water azeotrope which prevents the recovery of pure 200 proof ethanol. Regardless of the source of the water- in the plant, in the air, or condensation in cold vessels- the azeotrope is extremely difficult to break, resulting in recovered ethanol less than 185 proof. As more water comprises the ethanol, the solvation strength for CBD decreases. This is another often overlooked detail which can have a drastic effect on the cost of consumables. There are solutions for reproofing ethanol, such as molecular sieves and reproofing stills. The best solution, however, may be the choice of evaporation equipment which could avoid the problem altogether (see Evaporation Equipment section).

The next best way to maximize your ethanol savings is by using the same volume of ethanol multiple times for extraction. The reason behind this is simple- at a typical 1:1

hemp(lb):ethanol(gal) extraction ratio, the solvation capacity of ethanol far exceeds what will be extracted in the first batch of biomass. The number of batches which can be extracted by the same volume of ethanol depends on the CBD potency of the biomass, of course, but typically 7% biomass can be extracted at least three times before the ethanol nears saturation and solvation strength diminishes. Note: extraction of pigments and waxes also diminish solvation strength so cryo temperatures must be maintained in order to reuse the ethanol several times.

Another way to cut ethanol costs are through purchasing 190 proof denatured ethanol. Denatured ethanol does not incur the federal excise tax so the cost is significantly cheaper than 200 proof. It is important, however, to use ethanol denatured by n-heptane which is a food grade denaturant but be aware that the EPDM seals most likely in your extraction and evaporation equipment are not compatible with heptane. Another option is to purchase non-denatured 190 proof ethanol (w/ 5% water) but the small savings compared to 200 proof does not justify the dilution.

The final cost factor that makes ethanol extraction the best choice is the price of equipment. Being non-volatile, ethanol extraction equipment is designed to operate at atmospheric pressure, allowing for much more affordable materials, closures, valves, and safety measures. Furthermore, the highly competitive market of ethanol equipment drives the prices down.

Contact Cedarstone Industry to Learn More About Supercritical CO2 Extraction Equipment

To get your extraction system contact Cedarstone Industry today at (281) 397-3700. Or you can check out there about us and products and services to learn more. Choose ethanol when shopping for extraction equipment rather than supercritical CO2 extraction equipment.