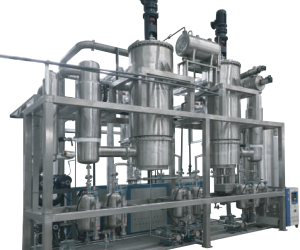

Ethanol Extraction Systems

Our ethanol extraction systems are top of the line at Cedarstone Industry. The ethanol extraction process can be tedious to handle. However, our machines are up to the task. Due to its high efficiency, it is ideal for the commercial producer. It is much more efficient and cost-effective than CO2 supercritical extraction. What is the CO2 extraction, you ask?

The process creates change phases in carbon dioxide. The CO2 supercritical extraction is versatile, creating multiple end products by controlling temperature and pressure. It allows for differing components of a plant to drop off during the phase changes. The design of the system also allows for the separation and collection of these constituents in a single extraction. It is safe, clean, and pure.

Nonetheless, if CO2 supercritical extraction is already capable of a quality extraction, imagine what our machines can do. Ethanol is one of the oldest methods of extracting desired oils from the designated plant. We’ve taken its already unique ability and amplified it to a new level. When at freezing temperatures, ethanol extracts specific terpenes and cannabinoids from cannabis. Undesired waxes and lipids are left behind. Our machines produce a higher yield with reduced time on a larger scale.

Ethanol Extraction Systems

The steps of our system consist of the following:

- Extraction – The plant material or biomass is put inside of our machine’s vessel. While inside, a solvent (in this case, ethanol) removes soluble components followed by the filtration and separation process.

- Centrifuge Extractor – Also known as a centrifugal contractor, uses the rotation of its rotor. It mixes two immiscible liquids outside the rotor. This mixture separates the liquids due to the field of gravity inside the rotor. This provides an efficient way to extract from one liquid phase to another continuously. Thus, saving time and energy.

- Distillation – A liquid or component is isolated by selective heating, vaporization, and condensation during this step. Steam distillation, for instance, is used to capture Terpenes. Our vacuum distillation uses this process under reduced pressure. Placing the liquid under the vacuum at a reduced pressure allows distillation to occur at a lower temperature. By lowering the liquid boiling point, it increases the rate of distillation and reduces exposure to temperature-sensitive components.

- Decarboxylation – This step is a chemical reaction that removes a carboxyl group and releases carbon dioxide. The removal of carbon dioxide transforms THCA to THC and CBDA to CBD.

- Crystallization Reactor – Crystallization is one of the world’s most used technologies for chemical industries. In short, it optimizes separation and purification.

- Chromatography – A lab technique used for the separation of a mixture is the definition of this term. The mixture passes through a medium separating the components.

Though there are different techniques for ethanol extraction work, these steps are the basic methods. Our machines articulate and use precision extraction solutions for quality. We are one of the leading distributors for our ethanol extraction equipment in the United States. We have service and products used on a large scale, including companies like Coca-Cola and Heineken.

Ethanol Commercial Purpose

Ethanol has extensive use for commercial purposes. The compound can be obtained through the fermentation of sugars and starches by chemical synthesis. One of its primary applications is as a psychoactive drug. Have you ever wondered what causes the “drunken” feeling when consuming adult beverages? Ethanol is responsible for the neurotoxicity of alcoholic products when taken in sufficient quantities.

Cannabis Industry and Ethanol Extraction

You ever wipe your hands with sanitation wipes or clean them with hand sanitizer. Ethanol is also found in those types of products acting as an antiseptic. You might not know this, but the liquid is quite amazing. It is responsible for killing organisms by breaking down its protein. Protein is the building block of DNA, so I guess you can say ethanol attacks organisms at its core genetic makeup. Due to this attribute, it is also the enemy of bacteria, fungi, and viruses.

As you have probably guessed, ethanol is invaluable to us. Medicines, including acetaminophen, gasoline, iron supplements, and more use ethanol! If you are in the commercial industry and your product involves high yields of ethanol, consider our machines. For example, if you sell alcoholic beverages, alcohol extraction is the main ingredient for your drinks. The alcohol in those drinks is basically ethanol.

Systems and Services

Since 1992, we have been one of the leaders of an ever-growing industry. As an industrial stainless steel manufacturer, we provide all types of equipment. Stainless vessels, mixing tanks, aseptic tanks, crystallization reactors, and others are well within our capabilities. We know how crucial product demand can be for industrial services. Because of such demand, our customers come first.

We lead in the industry for both competitive prices and customization. Our installation experience is second to none, providing excellent quality control. We advocate professionalism and excel in work ethic. Due to our drive, there is no shortage of hard workers in our business. Each employee is dedicated to making top-notch products and providing exemplary service.

These skilled workers work in a plant of over 300,000 square feet. Needless to say, our manufacturing capabilities are high. With highly skilled engineers, it’s hard to not be good at what we do. Check out what we do at our gallery! Our manufacturing services also do not disappoint.

Ethanol and Cedarstone Industry

Leading Manufacturer of Extraction Equipment

Plant matter can be tedious for solvent recovery, especially ethanol extractors. However, we’ve had years to refine the process to a tee. Our product does not disappoint in delivering high yield and efficiency. The closed-loop extraction we use allows solvents to be reused and reduces the risk of explosions. The reusable ethanol solvent is key to saving money and time when it comes to your industry needs.

Cedarstone Industry is proudly certified by The American Society of Mechanical Engineers. We are more than capable of providing what you need. Our services range from brewing tanks to sanitary fittings. Because of our multi-task attitude, we can engineer, construct, commission, or service in your plant. Give us a call at (281) 397-3700. We can satisfy you with our ethanol extraction systems.