A Cedarstone Industry crystallization reactor is built to last. If you need an industrial crystallization tank, proper functionality is your first, non-negotiable requirement. Our tanks allow for a safe, consistent chemical process for every batch. However, you must consider a few other factors before you make your final purchase decision. If you want to make the best investment, you need a reactor from a company that has built and provided commercial crystallization reactors for several years. Cedarstone Industry has been around for a long time, and we build tanks with the same durability and endurance. Inside and out, our reactors are designed with you and your business in mind. Below, we’ll discuss a few of the benefits that are unique to a Cedarstone Industry tank. Then, we’ll tell you about a few of our other products that you may find useful for your business.

What Makes Our Crystallization Reactor Special?

Some of the qualities of our reactor tanks are practically required. For example, you need a pressurized tank that meets ASME Boiler & Pressure Vessel Code. However, you might be surprised by how many tanks you can find on the market that don’t meet these standards. Unfortunately, some companies opt for these non-certified tanks because of the lower price tag. However, having anything less than the best equipment for your pressurized chemical reactor will usually cost much more than a quality piece of equipment. Keep yourself and your team safe with our certified machines. Fortunately, there’s more than one reason to love our reactors.

Superior Construction

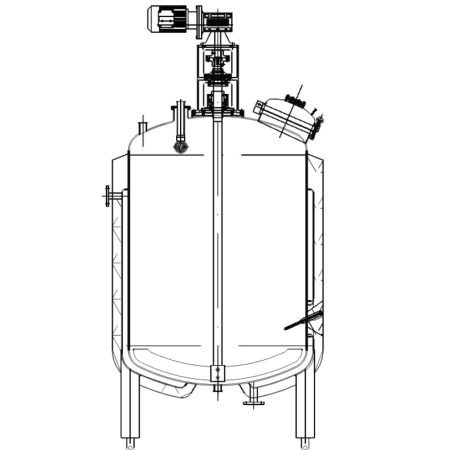

From our 60 gallon option to the 50,000 crystallization reactor, each of our tanks is designed and built by experts. Our tanks don’t have dead corners, which makes for much easier cleaning and crystal retrieval. Furthermore, we use sanitary fittings and seals that can handle the highest pressures and keep your batches completely free of contaminants.

304 or 316L Stainless Steel

Our stainless steel tanks control crystallization quality. With other, less expensive metals, you risk altering the chemical reaction. Color, consistency, and other physical properties may be altered by materials such as iron or copper. However, you also have to be wary about which type of steel your tank is made of. We build our Cedarstone Industry tanks out of either 304 or 316L stainless steel. Other grades of stainless steel, such as 303 or 202 stainless steel, don’t provide the same benefits. For a crystallization reactor, you’re going to need a corrosion-resistant tank. That means you need 304 stainless steel, at the least. Our 306L stainless steels offer even more corrosion protection, but also come with a heftier price tag. Nonetheless, both of these materials stand head and shoulders above the most elaborate reactor made of another type of metal.

To make great metal even better, we polish our stainless steel. This gives our crystallization reactors superior durability. Polish gives your tanks a protectant. While stainless steel in and of itself is a superior metal for industrial and commercial use, polish maximizes its effectiveness. As a result, your reactors will last longer and withstand more use than a non-polished tank. Not only does Cedarstone Industry polish the tank itself, but we polish every single metal fitting and component that we install on the device.

Jacketed Reactor

You can surely conduct crystallization in a single-wall reactor. However, the crystallization processes will greatly benefit from the jacket. A jacket allows you to process your materials under the best temperature. With consistent temperature control, you have much greater chances of a consistent reaction than you would with a non-jacketed tank. At Cedarstone Industry, we construct a variety of jacket options. We can fit your rector with a dimple jacket, coil jacket, or a full jacket. We can discuss your particular goals and chemical process to help you determine which jacket is best for your tank.

Optional Configuration

At Cedarstone Industry, we’re known for our ability to create the perfect tank for you and your chemical engineers. The chemical industry is so vast, we know that two companies might need entirely different reactors to achieve their goals. As mentioned above, we can alter the type of jacket of your reactor. However, we can configure many more unique settings for your tank. Optional fittings include a sterile air filter, thermometer, cleaning ball, liquid level control system, and more. You’ll be able to monitor and control every aspect of your chemical reaction with our measurement and adjustment tools.

Other Cedarstone Industry Products

After the crystallization process, where does your new material go? More than likely, you need a storage tank or another piece of equipment before you are ready to package your product. Cedarstone Industry offers a large suite of stainless steel products for your industry. All of our equipment is constructed of the same durable material and designed for easy cleaning. Furthermore, just like your new reactors, we can fit your tank with optional controls. If you need a custom solution, our designers can create the one-of-a-kind storage tank or mixer that meets your business needs. Our other tanks and equipment includes:

- Storage Tanks

- Mixing Tanks

- Food-grade Hoses

- Fittings, Valves, and Clamps

All of our tanks and components meet the applicable standards and have certification. Furthermore, we put the same great care into every product we provide. Thus, most of our other tanks are also stainless steel, insulated, and customizable. To learn more about our other products, check out our website.

Call Cedarstone Industry Today!

If you need to control crystal size or crystal growth, you need a crystallization reactor that can achieve the results that you desire. That means that you probably need a custom tank from Cedarstone Industry. Call us today at (281) 397-3700 or use our online form. We’d love to talk to you about your goals and create a system that allows you to do more, faster. You can trust the company that has built pressure tanks and crystallization reactors for nearly three decades.