Are you in the market for commercial distilling equipment? Perhaps you are opening up your new bar or building a brewery and need the equipment to begin the process. Cedarstone Industry can take care of these needs and make sure that you get the best care possible. We have been working in this industry for a long time and understand the pressure. The importance of having the best equipment possible is critical. While the craft of making beer or whiskey is certainly an art, it is still very much a science.

Use Our Beer Fermentation Tanks For Your Distillery Equipment

There must be incredibly precise sensors and strong enough materials that can ensure the alcohol is encased and protected from all of the different elements. That’s where our tanks and other distilling equipment become effective. Our units have an exceptional caliber to uphold. They come complete with dozens of different customizable options that you can pick and choose from. We’ll elaborate on the capabilities that you have as we continue. Hopefully, after this article, you will have made up your mind on the best equipment for your distillery. Cedarstone aims to impress!

Process of Distilling Alcohol

Distilling alcohol is an ancient and cultural activity. Many peoples from all over the world have their own form of distilling alcohol. In fact, that is one of the prime reasons why there are so many different kinds of alcohol, to begin with. They have been trying and retesting different methods of time and time again. Sometimes, something magical arises, and a delicious flavor of alcohol was created. Over time, the process is perfected until there is a viable recipe to follow.

While every specific recipe of brewing is going to be different, it involves a similar process. To give you a basic understanding, we’re going to describe the essential steps for the distillation system used in making beer.

- Creating the wort is the first part of the process. This involves an extraction process that begins with the mashing of the malt and other grains. Then it is brought to a boil where other ingredients like hops are added to provide the flavor, aroma, and color of the beer. Afterward, the solid particles that originally made the wort are separated from the final product. At this point, it is ready for the fermentation.

- Fermenting your beer is a process where the sugar in the wort turns to alcohol. The yeast will feed on the wort to produce a mixture of alcohol and carbonation. This is essentially what gives the beer it’s life and intoxicating effect. It is a very important part of the brewing process and is one of the most necessary aspects as well.

- Once time has allotted, the beer is allowed to filter into the next tank where it sits and matures. This helps carbonation and flavor grow and intensify. At this point in the process, the beer is capable of being bottled, canned, kegged, or served directly out of this tank.

Our high-quality brewhouse perfect for craft distilleries

What Consists Of Commercial Distilling Equipment

Before you get just any combination of commercial distillery supplies, you have to know what all the components are and why some are better than others. There will be instances when you find that one is more appealing due to preference, but that will be after you narrow down the best options on a basis of quality. We will depict each piece and explain how it functions with the rest of the unit to get the final result.

Mash Tun

This is the first step to the brewing process and should be taken very seriously. During this step, the malt is added to heated, pure water. Through time and temperature control, the substances mix and break down all of the micro compounds. This is done in a large tank called a mash tun. It must have very precise cooling to ensure the chemicals are broken down. It’s very important to have the proper water filter as well, as the variance in acidity and minerals could disrupt the activity of the enzymes that are necessary to create the wort.

Boiler

Heat is one of the most important factors in this process. Whenever the heat is present, the wort warms to a level that is highly mixable. This is usually just before the fermentation process. It is the point when you make the body of the beer. They will use hop resins and fermentable syrups to reinforce the flavor of the brew. The intense heat allows it to finish in around 2 hours with a full-flavor effect. Afterward, the wort gets filtering and is left clear and potent. We have boiler tanks as well as the commercial distillery supplies you need to need to find success.

Fermenter

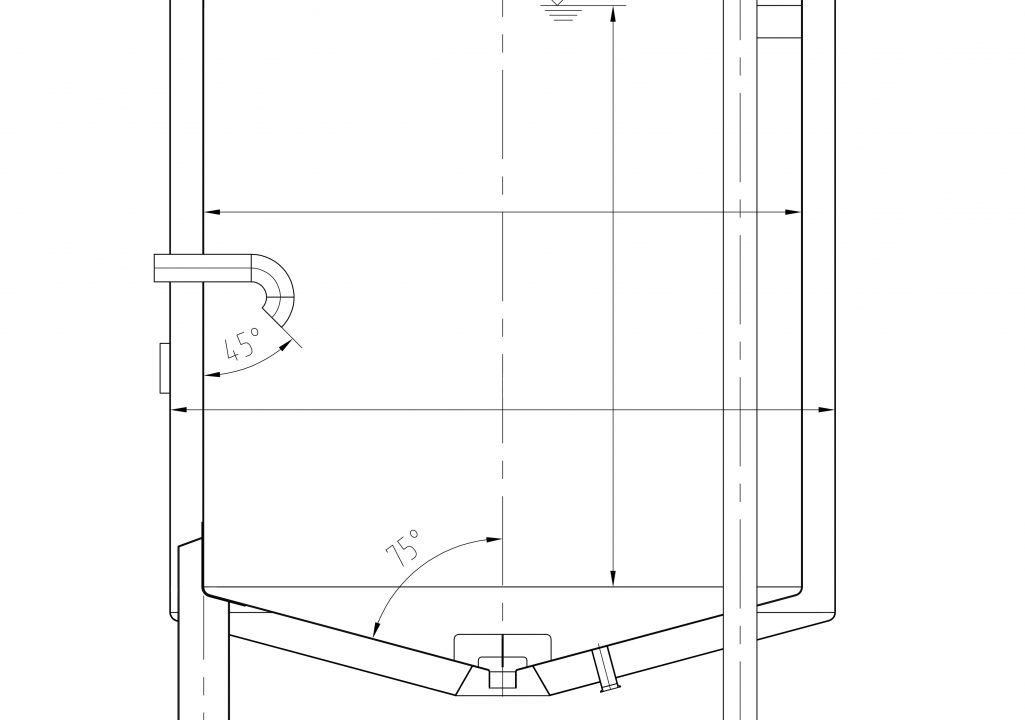

These tanks are essential aspects of your distilling process. When the time comes to turn the substance into alcohol, this is the tank for the job. It will usually come in a cone-shaped bottom for the cleanup. This means that the cone will be collecting all of the trub and yeast that was used to turn the wort alcoholic. The cone shape makes it easier for the piece to be removed and clean sanitarily. As a result, you can do multiple fermentation in one vessel. Our tanks are all stainless steel and capable of the customization you need for your location.

Our tanks are exceptional and made of the highest quality stainless steel!

Brite Tank

As we mentioned earlier, once you have taken the fermented wort and filtered it, you will put it into this tank. It is closely related to the fermentation tank; however, it will not contain the yeast or the trub. Therefore, it can settle and sit for long periods. Usually, this type of tank his pressurized as well to allow for tasting. Our tanks are capable of offering this as well, and they also have cooling systems that can help maintain the atmosphere for the beer.

Contact Us for Your Commercial Distillery Equipment Components!

When you’re on the lookout for high-quality commercial distilling equipment, you can look to Cedarstone Industry! We have an exceptional range of items that you can explore. We make these with the express purpose to make your brewing process easier and more fluid. The standard of our tanks and filters is capable of making a noticeable difference in the flavor. You can make drastic changes to your beer simply by the change in equipment. If you’re looking to get in contact with our representatives for your micro-distilleries, visit our website or call us at (281) 397-3700. We hope to hear from you soon!