Cedarstone Industry offers the highest grade quality extraction systems through its Centrifuge Ethanol Extraction. With our large scale extraction machines all over the United States, Cedarstone Industry promotes proper extraction processes so that you use your plant material effectively. With companies of all sizes using our ethanol extraction systems for their cannabis oils, we know just how important it is to have the right equipment. Give us a call today at (281) 397-3700 to find out everything about our different extraction methods. Whether you’re doing alcohol extraction, co2 extraction, or cannabis extraction, Cedarstone Industry can help!

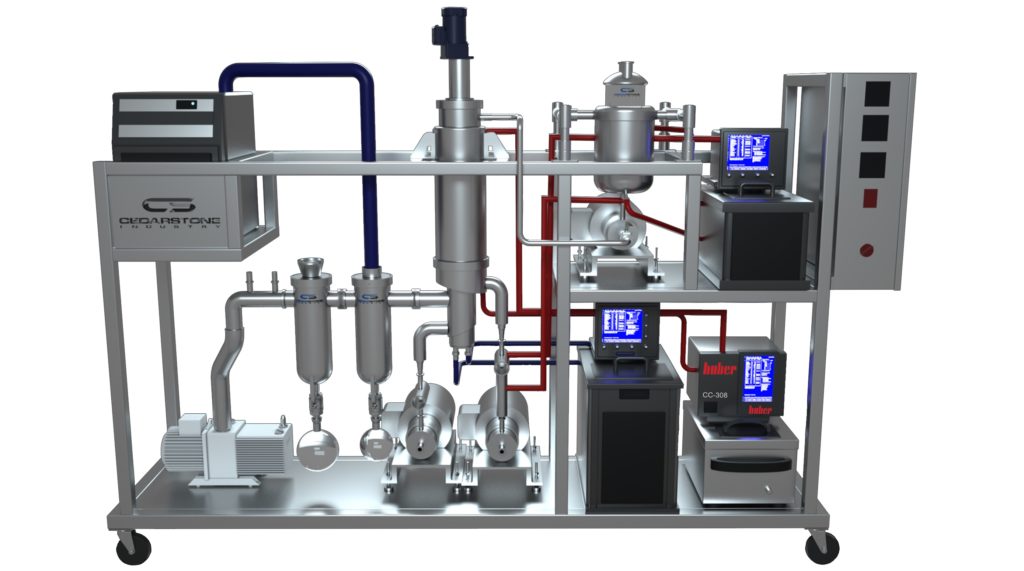

Ethanol Centrifuge Extractor

Why Cedarstone Industry For Centrifuge Ethanol Extraction?

Our expert team of designers, builders, engineers, and sales representatives have one goal in mind: Get the client what they need. Sometimes, that means educating them on how to extract hemp oil and other essential oils properly. Our ethanol extractors are top of the line products that utilize the latest extracting processes. Our centrifuge ethanol extraction process is carefully crafted by our team of seasoned veterans to ensure the best quality and purest CBD.

How We Use Our Centrifuge Ethanol Extraction

Our ethanol extraction method bases itself in cold ethanol. Our machines place the biomass into the rotor and are filled with cooled ethanol. Then, the machine spins at high speed to extract the compound from the ethanol. The process is primarily based on exposing the ethanol to low-temperatures and other hemp extraction processes. Our centrifuge equipment is manufactured to be easy to use and safe to operate by all qualified employees. They are also designed to be a time-saver because Cedarstone Industry knows how important our client’s time is to them.

The highest quality centrifuge extraction

Main Features Of Our Centrifuge Extractors

Our extractors comply with the latest standards and requirements of GMP. In addition, our machines are designed with safety and sanitation in mind. That’s why all of our tanks and extractors do not have dead corners, making them easy to clean. The SpinMatic150 and SpinMatic250 models are state-of-the-art machines designed for maximum efficiency and results. Cedarstone Industry extractors include automated fluid systems for ease of use and control. Our expert electrical design engineers and software design engineers focus on ensuring that our centrifuge extractors and other products operate to achieve maximum results.

Our stainless steel extractors are made with designs specifically for quality and reliability. With an explosive proof motor from Toshiba, Siemens PLC, inert air purging system and other UL certified components. The entire control is UL certified to be allowed to use in C1D2 environments. PSI is working diligently on the third-party review on our centrifuge and will finish the approval process soon( around Jan 2020).

What Makes Cedarstone Industry So Special?

It’s a fair question. It’s important to know who you’re doing business with and trust them to do the job right. Cedarstone Industry has been serving companies all over the United States for over 20 years. Our staff and the team of builders and designers manufacture all your brewing and extraction equipment. Whether you need mixing tanks, food processing equipment, distillation equipment, or sanitation equipment, Cedarstone Industry focuses on making sure all our products are up to your standards!

We’ve partnered with every kind of business, from large companies such as Coco-Cola, Heineken, and Blue Bell Creameries, to local breweries all over the nation. The reason companies choose us is because we value our clients’ needs, above all else. Our philosophy here is that mutual trust and respect leads to a strong, healthy work relationship. Therefore, Cedarstone Industry works tirelessly to ensure our teams always find a way to work together and make the best possible outcomes.

We Have Other Ways For Extraction Other Than Centrifuge Extraction!

While centrifuge extraction is a booming business in today’s world, we offer a variety of products for everything from brewing to sanitation. In addition, Cedarstone Industry offers services such as installations, tank polishing, and tank insulation. We also manufacture steel plating for as small as 10″ OD tanks.

Aside from tank maintenance, our engineers produce a variety of ethanol extraction tools and methods. So no matter what method of ethanol extraction your business uses, Cedarstone Industry has you covered!

Thin Film Distillation

Distillation

Our machines use different methods other than the traditional boiling point distillation. The process involves a unique approach, with the molecular distillation method. Molecular distillation uses a particular type of liquid-liquid separation technology to separate molecules using high-speed movement. Many consider molecular distillation to be the safest method for distillation, as it separates the thermally unstable molecules with low volatility. The use of distillation primarily serves to purify after extraction and oil deodorization.

Crystallization

Cedarstone Industry crystallization reactors focus on rapidly cooling the ethanol. This achieves a high purity CBD on a much larger scale without the need for complex tools. Like with our centrifuge machines, crystallization reactors come in a pre-made model. But don’t worry, we have no problem manufacturing tanks to your specifications!

Decarboxylation

Don’t let the name for this method scare you, Cedarstone Industry makes equipment to make this process as easy and efficient as possible. Decarboxylation enriches CBD and THC quality by exposes the plant material to heat. This process uses the heat to convert THCA to THC and CBDA to CBD.

Cedarstone Industry Wants To Help However We Can

Our staff always keeps the client’s requirements in mind at all times because we understand that your business is important. That’s why Cedarstone Industry works off of the idea that each client is unique and deserves extra special attention and effort on our part. With ethanol extraction becoming a major player in the business world today, it’s important to get your equipment from the right manufacturers.

Other companies will try to sell anything they can but lack the proper experience. Not us. At Cedarstone Industry, we use our 20 years of practice and experience to ensure our clients get everything we can provide them.

Contact Us Today For Your Centrifuge Ethanol Extraction Tools!

Make the right decision when it comes to your equipment. Make the decision that successful companies like GE Pharmaceuticals and Coco-Cola made; choose Cedarstone Industry. Whether it’s equipment or information, our staff are always ready and eager to aid you with your extraction needs. For additional information or questions, make sure to contact us and get your Centrifuge Ethanol Extraction today!