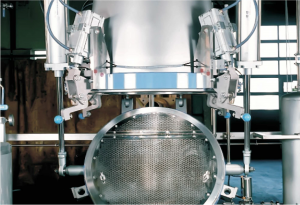

Extraction Vessel

Cedarstone Industry’s cannabis oil extraction machine is top of the line. Our oil extraction machine is capable of refining the process of extracting cannabis from plant material. Getting the necessary components from the plant matrix without receiving extra sediments. Cannabinoids and terpenes are essential elements to remove that are used for commercial industry related to cannabis products.

Moreover, if you’re a business who uses cannabis oil extracts as an ingredient in their product, you want the purest extract for a more high-quality product. By using ethanol as a solvent for the extraction process, cannabinoids and terpenes can be extracted from the plant. This essential process, which is even more efficient than supercritical CO2, is faster and more efficient by using our machines.

Components of our extraction methods feature:

- Extraction

- Centrifuge Extractor

- Distillation

- Decarbolyxation

- Crystallization Reactor

- Chromatography

Each process is critical in allowing the extraction process to be high quality and more efficient. After all, if you’re in a commercial industry requiring cannabis-infused products, the higher the yield, the better. Let’s see the importance of some of these methods in-depth.

Cannabis Extraction

Ethanol is the lowest capital and operating expense. Due to its feasibility, we use ethanol as a common solvent within the extraction process. Our use of the solvent is much more efficient and cost-effective when compared to CO2 and hydrocarbons. Our closed-loop machines make the process a safe method for cannabis hemp oil extraction. It not only extracts both water and oil-soluble compounds but when at freezing temperatures, ethanol can extract specific terpenes and cannabinoids from cannabis. At the same time, it leaves waxes and lipids behind.

Moreover, the supercritical CO2 extraction systems not only become obsolete compared to our machines, but you’ll see there’s no other efficient way. Also, this fact is even more apparent when taking a look at our centrifuge extractor. It is a part of our extraction equipment that uses a rotor to separate compounds by the gravity of its spin. During this action, the two immiscible liquids outside the rotor that are separated are then isolated by a vacuum. With the vacuum, the machine can isolate certain aspects within the liquid mixture.

The vacuum is part of the molecular distillation system. It is an exceptional liquid separation technology used to distinguish molecular compounds within the machine, such as CBD oil. The application we use involves:

Cedarstone Industry Extraction Machines

- Purification after extraction

- Vacuum distillation of terpenes, terpenoids, and cannabinoids

- Removal of chlorophyll, insecticide, and other residues

- The concentration of essential oils

- The deodorization of oil

More Applications of Our Cannabis Oil Extraction Machine

Furthermore, our decarboxylation system is responsible for decarboxylating the cannabinoids. Cannabis does not naturally involve CBD and THC. Instead, it is in the form of CBDA, which is inactive and needs to be unlocked to reap its benefits. Decarboxylation aids in this step when heating acidic cannabinoids. However, temperature control is crucial as the cannabis also de-carbs during the curing process when the leaves are left to dry out. Another reason why commercial industries need our machines is due to the delicacy of such chemical reactions.

Our machines also possess crystallization reactors. If you’re wondering what exactly happens during crystallization, it involves atoms or molecules arranging into a rigid crystal lattice. It may sound technical, but basically, atoms and molecules bind together with defined angles to create crystal shapes with smooth surfaces and facets. What does this entail with the cannabis oil extraction, you may ask? Our reactors achieve very high purity CBD on a large scale without using sophisticated equipment. Since this can get in-depth, check out some of our information on our site.

Additionally, chromatography is an essential part of our machine. It is a reliable purification and analytical technique that has been used for over a century. In 1897, an American chemist named David Talbot Day watched crude oil turning into bands of color as it seeped upward through clay. Later on, a Russian- Italian chemist used chromatography to separate plant pigments. Our chromatography equipment achieves the same principle with cannabis, by efficiently separating compounds through high-resolution technique.

Cedarstone Industry Equipment and System

As you can surmise, if you adopt our services, you will not be disappointed. We have been articulating our craft since 1992. The products and services we provide are vast. Shying away from a challenge has never been our forte. We serve big and small because we understand what the commercial industry needs to maintain high productivity. We ensure high quality and productivity when you use our machines.

Moreover, our services are not limited to cannabis oil extraction machines. We also provide services for the following:

Extraction vessel

- Brewing system and tanks

- Food processing equipment

- Cleaning and pasteurization

- Automation and control

- Mixing Tanks

- Stainless storage tanks

- Tank components

- Sanitary fittings

- Sanitary valves

- Food grade hoses

Also, if this selection of services is not enough for you, we provide other manufacturing facilities. We have a team of the best engineers ensuring your product is high end and works efficiently. Slacking in quality service is something we haven’t done for twenty plus years and will not start now. Our company is capable of engineering, constructing, commissioning, and servicing production lines to your plant. Your needs are our priority when it comes to the commercial industry. We do not disappoint.

Contact us for your Cannabis Oil Extraction Machine

The American Society of Mechanical Engineers proudly certifies Cedarstone Industry. Also, we are accredited by the National Board of Boiler & Pressure Vessel Inspectors as well as 3A 63-03 Sanitary Standards. Our superior quality services have proudly served Coca-Cola, Heineken, GEA, Tetra Park, and others. For a better range of the clients we service, you can check out some of our customers.

Plus, you can feel to contact us. Moreover, we can be reached at (281) 397-3700. Our hours of operation are Monday through Friday from 7 a.m. to 4 p.m. Moreover, our business categories include food processing equipment, manufacturing, metal fabricating, and stainless steel paint. Cedarstone Industry performs as a highly dedicated and well-oiled machine. Why not get your cannabis oil extraction machine from a company which ensures reliability?