While hydrocarbon extraction is a commonly used method, ethanol extraction is just as great, if not better. This form of extraction is great for producing high quality, cost-effective essential oils. You can count on Cedarstone Industry for quality extraction equipment.

The extraction process for oil products coming from plant material is not a cheap or easy one. It’s important to make sure you get the best extraction machines to make sure you get the most efficient and cost-effective results. With over 20 years of experience in the field, expect the quality equipment and services from the team here at Cedastone Industry.

Cedarstone Industry supplies the best processing machines

A little about us. We hold ourselves to the highest standards, and we have built our company on a strong foundation based on customer satisfaction. The goal here is pretty simple. We focus and work all our time and effort on providing you with the tools to succeed.

Hydrocarbon Extraction

This is an extraction method that strips cannabinoids, such as THC, and terpenes from cannabis plant material. The process butane as the solvent to extract concentrate. The extract concentrate creates cannabis oils, shatter, glass, hash, wax, and other products.

This is a clean method that that won’t leave hydrocarbon residue when properly utilized. At the tail end of the process, the extract will come out to be clean and will contain good levels of cannabinoids and terpenes.

Using Solvents for Extraction

Cannabis, like plants in general, produces essential oil. This essential oil can’t be melted off in a tea or washed away. After all, oil and water don’t mix. Solvents separate the oil from plant matter. Solvents allow extractors to concentrate cannabis resin into a product of its own. Furthermore, the oil concentrate can then be used or infused into other products, such as foods and topicals.

Extractors use various types of solvents that help concentrate cannabis essential oils. Ethanol, butane, and propane are all commonly used solvents that extractors use in their methods. Moreover, the solvents also have other uses. For example, solvents can extract resin from psychoactive cannabis varieties and non-intoxicating hemp cultivars alike.

One thing to note is that not all solvents and extraction methods are created equal. Some, such as CO2 and ethanol, are safer for consumers and processors alike. With that being said, these two processes also produce contrasting products.

Ethanol Extraction

Ethanol is, essentially, alcohol. During this extraction process, alcohol is a solvent. Unlike other solvents, such as butane, ethanol is considered a safe and clean solvent without much risk for toxicity. In the consumer goods field, ethanol is one of the safest solvents to use. This solvent will evaporate easily and poses little threat to human health. Unless you drink it, that is.

Extraction System

As an extraction solvent, ethanol is on the higher end in terms of efficiency. Alcohols are polar by nature, leading them to form bonds with water-soluble and fast-soluble plan compounds alike. This makes the solvent a great choice for a full-spectrum extract. Unlike other solvents, ethanol is not quite as picky about what it pulls away from plant material.

This leads to darker green colors and a more bitter taste during at-home ethanol extraction. On the other hand, professional equipment allows extractors to further purify the ethanol concentrates. Ethanol is also mixed with other solvents to produce extracts with specific properties.

How it Works

Commercial extractors use technologically-advanced methods for the extraction and purification of hemp resin. These extractors pass ethanol through plant material. At the end of the process, they recollect the ethanol, which can then be recirculated around the plant material multiple times.

This allows for the optimal extraction of the oils. The end product is oftentimes syrupy in the way it feels. Also, you’ll find that extractions from professional extraction machinery will be light to dark able in color.

CO2 Extraction

CO2 is carbon dioxide and can be used in the extraction processed when exposed to the correct temperature and pressure conditions. These extractions tend to be a light to dark amber in color and have a honey-like consistency.

Unlike ethanol, CO2 is very picky. It doesn’t extract the beneficial phytochemicals present in cannabis resin. A study published by Planta Medica in early 2018 discovered that extractions using CO2 can significantly change the chemical make up of cannabis strains.

How it Works

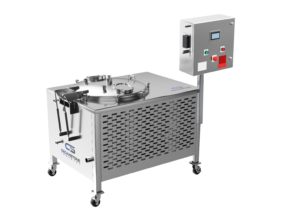

Ethanol Centrifuge Extractor

There are several moving parts in making a high-quality cannabis extraction. Many CO2 extractors use the supercritical CO2 method to extract cannabis resins. The CO2 is cooled and pressurized until it reaches a state that’s somewhere between the gas and a liquid.

The in-between phase allows CO2 to be passed through plant material as a gas. Moreover, it features many of the physical properties of a liquid. The machinery used in CO2 extractions will pressurize and chill CO2. Within a closed-loop system, CO2 is recaptured. Much like in the ethanol process, the CO2 process is clean and efficient.

Ethanol vs. CO2

While they do have their similarities, ethanol extraction is more cost-effective and safer when it comes to lab safety than the combustible CO2. While no method is perfect, ethanol extraction is one of the safest when it comes to drawing the subtle flavors, aromas, and synergistic compounds in the cannabis plant.

The compounds work in unison to enhance the beneficial compounds of hemp extracts. For this reason, many consider ethanol extraction as the best choice to make. Each method has its own pros and cons. While carbon dioxide is an excellent method when it comes to extracting nutrients from cannabis plants, the truth is that ethanol can be much more efficient.

About Us

Here at Cedarstone Industry, we work and focus on providing clients with turn-key solutions for brewery, extraction, beverage, and commercial food applications. Based in Houston, we manufacture stainless steel equipment such as storage tanks, aseptic tanks, crystallization reactors, and mixing tanks.

Over the last twenty years, we’ve manufactured superior quality processing equipment for companies in various fields. Over the years, we’ve supplied extraction equipment, stainless tanks, mixing vessels, pressure vessels, CIP, UHT, commercial beer brewing equipment, and more.

Don’t settle for Hydrocarbon Extraction or CO2 Extraction

Contact us today for a better alternative to Hydrocarbon Extraction. You can reach one of our representatives by calling (281) 397-3700. Or visit our Products & Services or About Us webpage to learn more about how we can help you. Choose ethanol over CO2 or hydrocarbon extraction, call us today.