co2 extraction

Are you searching for co2 extraction? Then you need to talk to Cedarstone Industry since they have the best technology to help you manufacture your product. Even though these guys are working in the Houston TX area, they supply equipment to companies all over the world. They have supplied brand name companies such as Coca-Cola, Bluebell, Heineken, and more. It doesn’t matter though whether your company is big or small. They provide machines for all companies.

These guys also not only provide machines, but they will also service your machine as well. So, there is no leaving you to wonder how to care for your new equipment. Instead, trust the guys who made it care for it for you. There are many uses for extraction equipment and many different types of extraction. However, either way, you will require a high-quality machine to get the job done. Whether the final product is CBD oil, essential oils, or cannabis oils, this company has you covered.

There are many methods of extraction, and it is important to know which one you will need. This is because each method yields different results. While some will have higher temperatures and pressures, others will have lower ones which will change the product you have. Let’s look at CO2 extraction, Ethanol extraction, and some of the extraction methods.

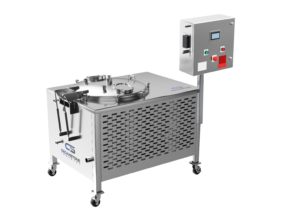

Filtration Skid

What is CO2 Extraction?

The simple explanation is that it is a process that requires pressurized CO2 to extract the necessary phytochemicals from raw cannabis or other plant matter. The finished product is clean cannabis extract with little to no impurities. This product is a lovely and versatile amber-colored oil. You can also create concentrates like shatter or budder or infuse food and drinks with it.

CO2 is also known as a turnable solvent, which means that it has properties that can be controlled by the user. This makes it very versatile in producing a variety of products because you can control the temperature and pressure. Coffee companies and essential oils both use CO2 extraction. It took a while for cannabis to implement this method into their practices because other methods are cheaper. However, they don’t produce a high-quality product like the CO2 method.

Other industries that use this safer method are the food industry, cosmetics, beverage companies. However, they also, at one point in the past, relied on risky extraction methods before turning over to CO2. Methylene chloride is a common solvent that was used for extraction. This chemical is still used in other industries, such as paint stripping, metal cleaning, and pharmaceutical manufacturing. However, OSHA considers this chemical to be a potential occupational carcinogen.

To avoid OSHA concerns, it is best to use CO2. It is clean, safe, and able to produce a clean, high-quality product that you can proudly place on the shelves. This is because CO2 is a naturally occurring compound. Even the FDA has said that it is safe for industrial extractions. It is also safer and more reliable than other hydrocarbons such as butane and propane. For CO2, the conditions to create a supercritical fluid are temperatures below 88 degrees. This means there is less risk of damaging the natural compound. It also allows you to pull from cannabis the cannabinoids CBG, CBC, and CBN. People often use these cannabinoids for wellbeing purposes.

What is Ethanol Extraction?

Ethanol goes by many names; it is also grain alcohol, ethyl alcohol, and is a colorless and volatile flammable liquid. Ethanol extraction is an effective, efficient, and safe for human consumption according to the FDA. You can find this solvent in the production of food preservatives and additives. Some of the most common food industries that work with ethanol are wineries and breweries.

This method is safer than butane and more effective than supercritical CO2. It also has more lenient storage limits, which allow a facility that is using ethanol to have fewer requirements. This puts fewer restrictions on a facility using ethanol while yielding large extract volumes. It can also eliminate the need for a dewaxing or winterization if the extraction is done properly.

These benefits can save a facility time and effort when it comes to producing a high-quality product. And just like CO2, ethanol is fantastic for creating full-spectrum hemp extracts and tinctures.

It is also considered a renewable resource because it is derived from corn. Ethanol is a class 3 solvent with low toxic risks in pharmaceutical manufacturing. It is popular for its ability to leave little to no residual solvent behind.

Ethanol Recovery

Supercritical Extraction

Supercritical extraction is also supercritical fluid extraction or SFE. This is used in a lot of industries such as the cosmetology industry, pharmacology industry, essential oils, and the cannabis industry. It will take CO2 and use high pressures and temperatures to turn it into a supercritical fluid. This fluid binds with the plant matter and dissolves the porous material leaving behind the desired compounds.

This is the favorite out of extraction processes, especially for the cannabis industry. The downside of this process is that some terpenes are too delicate to be subjected to extremely high temperatures and pressures.

Subcritical Extraction

This is a similar process but requires a lower temperature and pressure. Using subcritical extraction takes longer and produces less than supercritical extraction. This makes it perfect for more fragile material. The other difference between supercritical and subcritical is that supercritical produces a substance with the consistency of peanut butter, while subcritical produces a consistency of molasses.

This extraction process provides full-spectrum cannabis products. The reason this works is that subcritical extraction holds onto the plant’s sensitive materials. The best method of extraction depends on what you are trying to produce. It also depends on if you want the process to be faster or more sensitive.

The Cost of The Machines

These machines can be quite costly when it comes to set up. However, this is because of the quality that they produce. These machines can cost thousands sometimes tens of thousands, but they will always provide you with a product you can be proud of. This equipment also requires a decent amount of training to be able to use. It isn’t worth cutting corners on.

These processes are also effective in killing bacteria, mold, and other things that could be problematic for your consumers. By investing in one of these machines, you are giving yourself one of the best methods of production.

Choose Cedarstone Industry to Be Your Supplier

To get your very own extraction system, call Cedarstone Industry at (281) 397-3700. You can also learn more about them and their products and services. So, pick Cedarstone Industries and choose ethanol extraction when browsing for CO2 extraction.