Cedar Stone Industry is proud to provide CBD extraction equipment to the new and budding cannabis industry. We are a leading stainless steel manufacturer. Our clients have included Bluebell, Heineken, Anheuser-Busch, GEA, Tetra Pak, Coca-Cola, and GE Pharmaceutic, as well as others for over twenty years. We are now in the business of providing oil precision extraction solutions.

CBD, or cannabidiol, is only one of the 113 identified cannabinoids in the plant Cannabis Sativa. But it makes up forty percent of cannabis extract’s active ingredients. THC, the psychoactive cannabinoid found in marijuana, makes up the other majority. During the extraction process, we separate CBD from THC, so it has none of the psychotropic effects usually associated with marijuana. This means one can benefit from the uses of CBD without going through any of the mind-altering effects. It is a natural plant material and extract oil.

CBD Uses

Only recently, as of 2019, has clinical research begun on the plant’s medical uses. There has been good starting evidence that it can be useful in treating many disorders or at least lessen severe symptoms. Even before trials began, it was already in use, and its effects were already acclaimed.

Today, the FDA has approved CBD for the treatment of several types of epilepsy. For example, Epidolex contains CBD oil, and doctors prescribe it for the treatment-resistant forms, Dravet syndrome, and Lennox-Gastaut syndrome.

While on the topic of seizures, research is ongoing to see how it can treat other neurological disorders. Sativex, a prescription-only nasal spray, has been used for Multiple Sclerosis. Researchers are trying to figure out how cannabidiol can help with conditions such as bipolar disorder, Crohn’s disease, diabetes, dystonia, fragile- X syndrome, GVHD, insomnia, withdrawal, Parkinson’s, schizophrenia, and social anxiety disorder.

For some professional and amateur athletes, CBD has helped their game. The World Anti-Doping Agency removed it from their banned substances list. Furthermore, many professional athletes have begun endorsing CBD for companies manufacturing the oil for sports. The NHL Alumni Association started to research to see if it could help head-injured players.

CBD Extraction Equipment Process

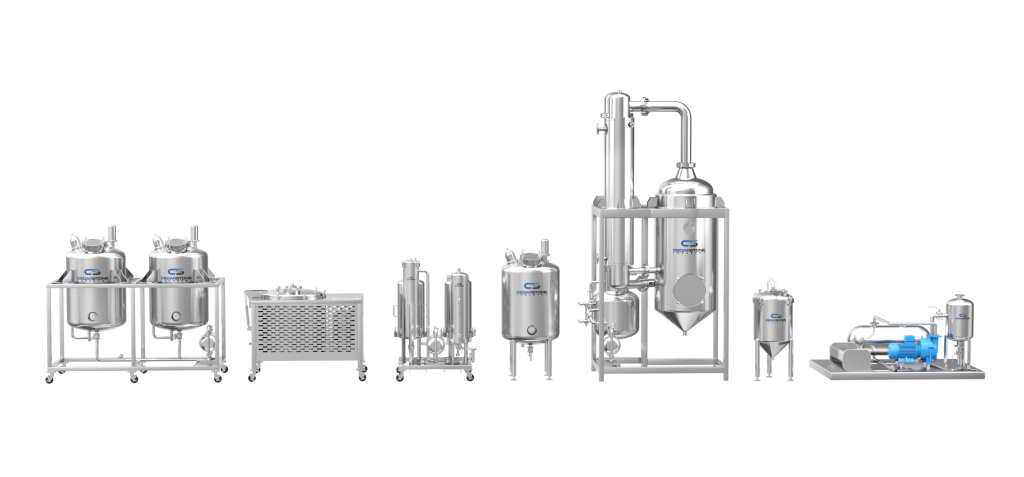

The process of extracting CBD oil from the rest of the plant is complicated. In order to get the best quality product and to have everything running smoothly throughout, you need quality equipment for each step of the way. Fortunately, our durable hardware of high-quality material is built to last. Cedar Stone Industry supplies the right machinery for the whole process, so clients can produce the best product. From the extraction to the distillation and crystallization, Cedar Stone Industry has what you need.

You can find the list of processes we support below.

- Extraction

- Centrifuge Extractor

- Winterization

- Solvent Recovery

- Decarboxylation

- Distillation

- Crystallization Reactor

- Chromatography

Cedar Stone Industry’s CBD Extraction System

If your business needs oil extraction machines, then we can take care of it. As a leading manufacturer of stainless steel, we provide the best in industrial equipment. We have quality closed-loop low-pressure ethanol extraction systems. During extraction, an ethanol solvent removes soluble components from the biomass inside the extraction vessel. Afterward, filtration and separation follows. Cedar Stone Industry sells the CEX Series Extraction Systems equipment. The system includes:

- Pre-Chilled, Ethanol Tanks Module

- Ethanol Centrifugal Extraction Module

- Filtration Skid Module

- Ethanol Recovery Module (Falling Film Evaporator/Wiper Film Evaporator)

- Vacuum Skid

- NEMA 4X stainless UL listed control

- Explosive Proof (Class I Division I) Intrinsically Safe, ATEX/SGS Certified Control Tablet

- UL Listed Pumps and Integrated Piping

- C1D1 Remote Control Tablet

- Windows OS driven system, Siemens application

- Class I, II, III Division 1 intrinsically safe control tablet

- Certified by ATEX/IECEx Zone 1, SGS to UL913C I, II, III Div 1.

- Rugged purpose-built control tablet used in Zone1/Division 1 hazardous areas

- Real-time Wi-Fi connectivity to control panel located within the safe room

- 1’’ WUXGA Display, 1920×1200 resolution

- Up to 12 hours of browsing (3.8v, 8700mAh, 33Wh battery)

Our Centrifuge Extractor

While the CEX Series Extraction Systems equipment includes a centrifuge, this module is an ethanol extractor. For a different extraction method, our centrifuge extractor uses chilled ethanol with a rotor barrel to bidirectionally extract from the biomass at high speeds. Our centrifuges are easy to operate, maintain, and configure to specific settings.

Its turn-key systems include fully adjustable agitation speed and time settings. Additionally, this system uses a UL listed Class 1 Division 2 Proof Control Panel and uses Siemens PLC and a touchscreen, with an advanced control system and HMI operation interface. Moreover, they have an automatic valve that you can configure to realize automatic control of feeding and discharge. It is of a completely modular design delivery, meaning the is no need for on-site installation.

Its turn-key systems include fully adjustable agitation speed and time settings. Additionally, this system uses a UL listed Class 1 Division 2 Proof Control Panel and uses Siemens PLC and a touchscreen, with an advanced control system and HMI operation interface. Moreover, they have an automatic valve that you can configure to realize automatic control of feeding and discharge. It is of a completely modular design delivery, meaning the is no need for on-site installation.

Our centrifuge is also in compliance with the latest standards, directives, and GMP requirements. Moreover, it is pending Peer Review for PSI (Pressure Safety Inspectors). Motor transmission parts are completely enclosed to ensure safe operations. Finally, it uses an explosive proof motor form Toshiba or of an equivalent model.

The metal is of 316L material and EPDM food-grade seal to provide and achieve reliable sealing of bearing. Also, the design optimizes to allow temperatures of -60 degrees Celsius during extraction. And the outer stationary barrel has a cooling jacket. The model has a sanitary rating, internal Ra of less than or equal to .2 um.

The Rest of Our Cannabis Extraction Equipment

We provide all the equipment necessary for the CBD oil extraction and distillation processes. If you are looking for any others, we might still carry them:

Molecular Distillation

Molecular distillation is different from the usual boiling point of different separation principles and instead uses special liquid-liquid separation technology. It is considered the safest distillation mode for separating and purifying thermally unstable molecules with low volatility and elevated boiling point.

Decarboxylation System

CBD and THC do not naturally exist in the cannabis plant. Instead, CBD needs to be brought out of its precursor, Cannabidiolic Acid (CBDA).

Crystallization Reactor

CBD that has tested above 80%, winterized and distilled, can go through our turn-key system and achieve high purification.

CBD Extraction Equipment

We can help you if you are a new and emerging CBD oil manufacturer get started. On the other hand, if you are a well-established manufacturer, we can set you up with new CBD extraction equipment as soon as you need it.

If you have any questions regarding our products or services, do not hesitate to contact us at your earliest convenience. Our customer service representatives are friendly, knowledgeable, and eager to help. So, give us a call today. You may also fill out the extraction system equipment form for information. We want you to have access to information on your machinery before and after your purchase.

Our office is located in Houston, Texas, and you can find our hours on our contact us page. But, we provide our equipment all over the nation. You can email us at sales@cedarstoneindustry.com or call us at (281) 397-3700. Do not hesitate to get in touch with us for your CBD extraction equipment.